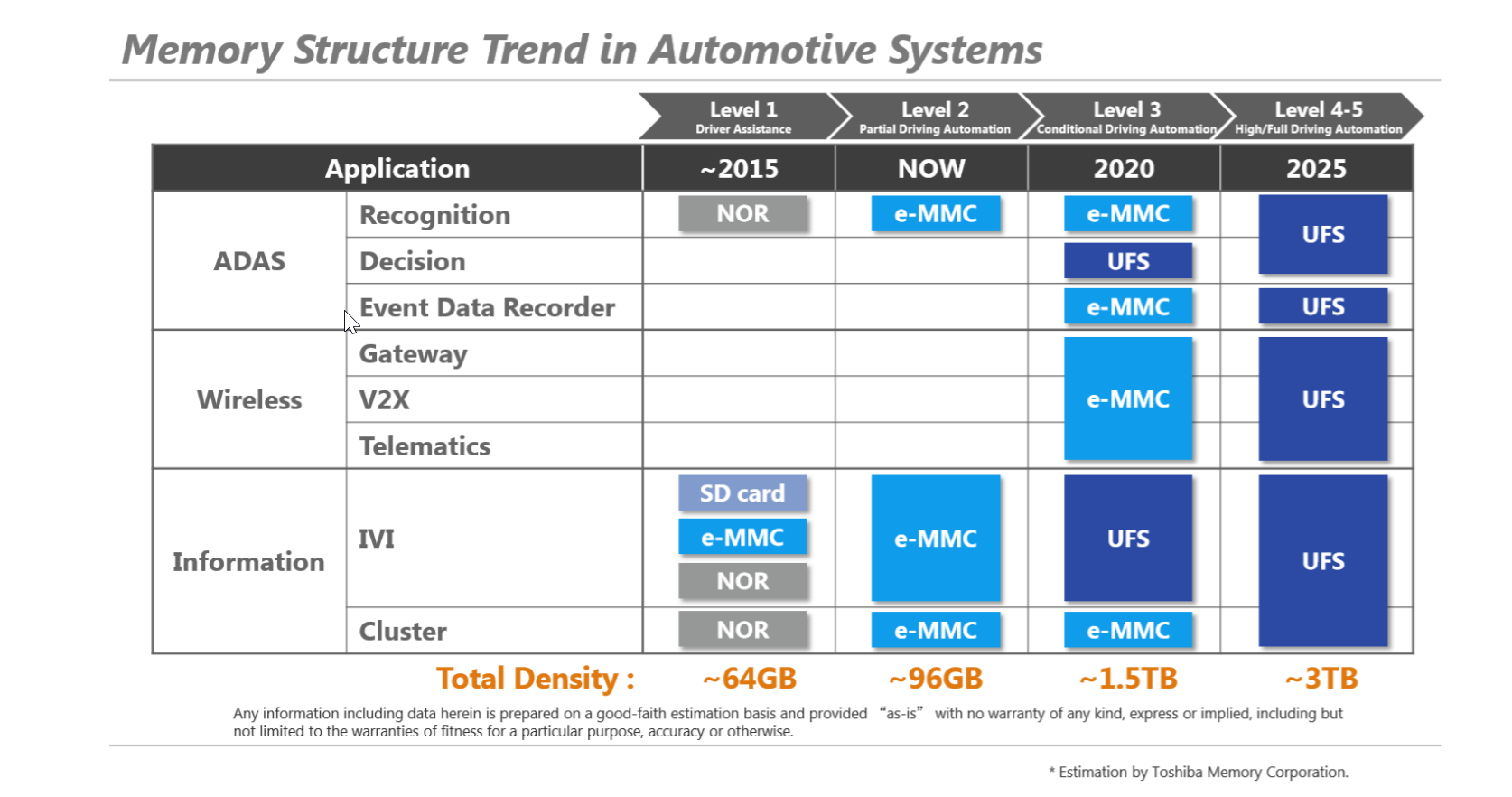

Connected and autonomous cars are driving technology changes that are disrupting the automotive electronics manufacturing process with the exponential growth in content, management of hundreds of software variants across a global supply chain, and the transition to the new Universal Flash Memory (UFS). Flash technology is expected to grow 40-80% per year to 1-2 TB per vehicle. Electronics systems suppliers and OEMs must plan strategically to securely and cost-effectively deploy large FLASH in their infotainment, ADAS, dashboard computing, and accident recovery systems. Automotive electronics manufacturers need to prepare today for this transition?

How can automotive electronics manufacturers optimize their programming process to support new programming requirements? Here are 5 questions to ask:

1) Can you upgrade your programming system to support large file sizes and UFS devices?

Not all programming systems can support UFS devices. If your programming system will not support UFS you will need to re-invest in a different programming solutions significantly increasing your costs. When investing in new capital equipment understand how extensible the programming technology you are purchasing is. This will protect your investment enabling you to meet future production demands.

2) What is the maximum socket capacity your programming system can support? New semiconductor technology and growing file sizes are driving changes to meet the increasing production demands. As image file sizes grow production throughput decreases. In this scenario, the two ways to improve production throughput is to either purchase an additional programming system or increase the socket capacity in your existing solution. Adding additional programming site(s) to your existing solution greatly reduces your total cost of programming. Investing in a programming system that has the flexibility to scale by adding additional programming sites greatly reduces the total cost of programming.

3) Does your programming system supplier have a strong history of innovation and financial stability to weather economic uncertainty?

The global economy is reeling from the impacts of the COVID-19 pandemic. However, new technology and electronic products still need to be produced. This will drive new requirements into manufacturing. Understanding the financial stability of your programming system supplier is critical. Will they be around when the economy is back to normal production levels? Are they currently investing in new programming technology to meet future requirements?

4) Does your programming system supplier have the industry partnerships to help solve critical technology questions?

New Flash technology including 3D managed NAND is evolving to stack more bits into smaller lithography packages. These devices can be susceptible to data retention issues if best practices are not followed. For automotive electronics manufacturers, it is critical that your programming supplier has strong relationships throughout the industry to develop best practices for pre-programming these devices. Ask if they have any published best practices.

5) Is service and support available when and where you need it?

In the global supply chain electronics manufacturing often require support in different regions and time zones. Local service and support are essential to help keep production running. However, with travel restrictions limiting onsite visits it is critical your programming system supplier has the tools to support remote training, installation, upgrades, and diagnostic capability in your local timezone.

The automotive standard for device programming

Data I/O, the world leader in automotive NAND FLASH programming, addresses industry trends with a 10X price/performance gain & extensible LumenX architecture. As the industry’s trusted supplier to the automotive market, our customers are asking for our help to streamline the programming process, maximize production and reduce costs while delivering the highest quality products. Data I/O has met this need by increasing the programming performance for UFS devices on our LumenX platform by a factor of four. The combination of programming technology, PSV systems, and software applications streamline the programming processes across the globe to deliver maximum production efficiency, quality and reduce costs that is unmatched by any other supplier in the industry.

The PSV family of programming systems is the world’s premier automated programming solution with the speed, flexibility, fast changeover, and small parts handling to manage any job for the lowest total cost of ownership. Engineered for velocity and versatility, the PSV family combines industry-leading robotics handling with revolutionary LumenX programming technology for the fastest device programming and highest socket density. With over 300 PSV systems installed globally, existing customers can protect their investments and easily upgrade their PSV systems to support UFS as their production requirements change. The combination of LumenX programming technology in a PSV system delivers the maximum performance, flexibility, and throughput for the best value.

Data I/Os Reliability in the Automotive Market:

- Automotive standard for UFS programming with 16 out of top 20 automotive electronics manufacturing using Data I/O’s programming systems

- Partnerships with all leading UFS suppliers including published best practices for X-Ray and Post Oven Reflow

- High Performance & Flexibility

- 2x programming performance gain up to 160 MB/sec

- 2x socket capacity supporting up to 112 sockets in the PSV7000

- History of continuous innovation

- Delivered a 10x performance gain on LumenX over 5 years

- 30% of sales invested in R&D

- Global Service and Support

- With over 60 service and support engineers located throughout the world, Data I/O is there to help you keep your production running. Data I/O also has a suite of tools to support remote, installation and diagnostic capability.

- Investment protection

- Extensible programming platform to meet your production requirements today and in the future.

{{cta('929969ea-9b84-40e3-bd96-735ef4e41cb2')}}

Flash technology is expected to grow 40-80% per year to 1-2 TB per vehicle. Learn how can automotive electronics manufacturers optimize production and save. . .